Combining SolidWorks And EDGECAM, Featuring At SolidWorks Exhibition

The unbeatable combination of SolidWorks and EDGECAM is featuring at the SolidWorks World 2013 Exhibition at Walt Disney World, Florida.

The exhibition, running from January 20 to 23, focuses on showing visitors how SolidWorks helps their CAD process to be faster and more efficient. And manufacturers find the philosophy extends to CAM when they use SolidWorks in conjunction with EDGECAM.

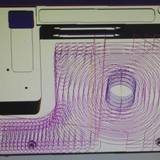

EDGECAM will be proving that fast, high precision machining is no fairy tale, when it demonstrates its long-standing partnership with SolidWorks, and its new Workflow automation system, along with its powerful Waveform Roughing strategy, which users say pushes the boundaries of traditional milling, and puts it ahead of the field.

Domenic Lanzillotta, EDGECAM’s Channel Manager, Americas Region, says both SolidWorks and EDGECAM are simple to use and easy to integrate. “We’ve been partners for many years, and with SolidMachinist for SolidWorks, we can take advantage of reading native file formats without the need for translation. This guarantees file integrity. Additionally, EDGECAM is fully associative, meaning that any tool engineering changes to the model are automatically recognized by EDGECAM, and tooling is automatically updated.

“SolidWorks users can also gain another benefit with EDGECAM’s Strategy Manager, which captures optimized machining processes and runs the entire sequence from a single click. This gives consistent reliable results, irrespective of the programmer’s skill.”

EDGECAM is exhibiting on Booth #706 at the show: venue, Walt Disney World, Swan and Dolphin, 1500 Epcot Resorts Boulevard, Lake Buena Vista, Florida. As well as highlighting the new and enhanced functionality in the latest release of EDGECAM – 2013 R1 – the team will also preview the forthcoming Workflow system, which provides a flow framework to guide users from a new CAD model to NC code as intuitively as possible. It uses guided automation to accomplish the tasks of Part Setup, Analysis and Feature Creation, Manufacture, and Deployment. The new tools aid in loading and positioning the component; choosing the manufacturing method and suitable machine tools; adding user defined stock or stock from a database; importing fixtures; selecting a machine and toolkit; and managing strategies to automate manufacture.

Amongst the existing functionality in EDGECAM 2013 R1 which will be demonstrated on Booth #706, is its new wire EDM feature; enhancements to the industry-leading waveform roughing cycle; a new time-saving option in the Profiling cycle to specify a chamfer or radius to break sharp corners, eliminating the need for deburring; and the ability to edit stock dimensions and re-pick geometry while retaining the stock shape. Changes to the stock are now considered automatically when regenerating the machining instructions.

EDGECAM: Booth #706.

Loading...

Loading...