Double Success with VISI and EDGECAM

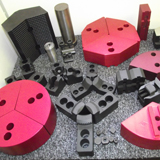

Thame Workholding, one of the world’s leading workholding specialists, not only uses VISI and EDGECAM to design and manufacture its own products, it also uses the software to create the fixtures that hold the material during its machining processes.

Based in Buckinghamshire, and recognised as a leading international provider of workholding solutions for all types of machining, Thame boasts over 15 CNC machine tools within a 10,000 sq ft. facility and is accredited to Quality Standard ISO 9001:200. Thame produce high precision bespoke workholding for a range of industry sectors including aerospace, motorsport, medical, marine and energy.

“Maximising our use of VISI and EDGECAM ensures we can deliver the same high standard products more efficiently.”

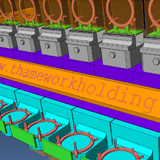

“We often create our own fixtures with VISI and EDGECAM to produce bespoke workholding for customers, as well as making our own fixtures to hold metal when we’re manufacturing our extensive range of standard jaw products on our horizontal CNC machines,” says Maurice Day, a Director of Thame Workholding.

After switching four years ago from 2D drafting to VISI’s powerful solid and surface modelling system, Thame find their design time is now up to ten times faster, depending on the complexity of the job.

Although the previous 2D package enabled them to undertake new designs, they could not work with the majority of their customers’ files, which were often created using a 3D system. “When we received a model we had to convert it from 3D back to 2D, meaning we were taking a backward step and it became a big time issue for us.”

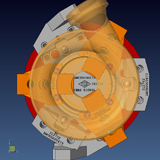

They invested in VISI for design and quickly found it invaluable for constructing and editing even the most complex 3D data. David Handley, Thame’s other Director says VISI’s feature-based modelling means they can quickly create a 3D model, and also generate a complete set of 2D detailed drawings, showing any view, directly from the master geometry.

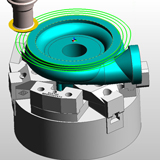

“With VISI, the model is almost the component, and as soon as it’s completed, we’re ready to cut metal. The model is seamlessly loaded into EDGECAM where the toolpaths are applied quickly and accurately.” Thame installed EDGECAM shortly after the brand was acquired by Vero Software in 2011, and it now drives a range of Mazak, Daewoo and Haas CNC machines, along with their recently-acquired 5-axis Matsuura MX-520 which utilises a 60 pallet Lang Eco Tower robot loader.

Today, 98 percent of their products are designed using VISI and machined through EDGECAM. They see that software combination with automatic 5-axis machining as the way forward. “We frequently load the tower and leave it running un-manned overnight, producing 20 complete sets of jaws with ‘lights-out’ machining.” Thame are planning to commission a second 5-axis machine in the not-too-distant future, as they are aiming to produce as many of their products in ‘one hit’ as they can, without the need for multiple set-ups.

David says Vero has revolutionised the way Thame operates in a very short time. “VISI, EDGECAM and 5-axis machining have proved to be such a great improvement to our design and production capabilities, it’s been fantastic for us. Many customers now provide a VISI compatible 3D model and some even use the popular software for their own design purposes because of its fully associative drafting capability.”

Offering bespoke solutions for customers’ workholding issues means their sales engineers frequently come back with a sample part that needs to be held, or a series of drawings. “The customer tells us the machine tool they want to put it on and the tolerances they need to keep to. All that information goes to our designers who then come up with the concept of how they’re going to hold the part; they then use VISI to create the 3D CAD model. Before we had VISI everything was so much slower...and every time we changed something we had to change it in every view.”

Concluding, Maurice adds they are now much slicker than they have ever been. “When everything runs smoothly through VISI and EDGECAM it makes our working day so much easier.” It has given them added confidence in their existing product range, and in developing new bespoke workholding.

“We have been well known for our standard products, bespoke turnkey packages and special projects for many years. However, maximising our use of VISI and EDGECAM ensures we can deliver the same high standard products more efficiently.”

As well as their own products Thame are UK agents for Lang Technik vices and automation, Samchully chucks and cylinders, Horst Witte vacuum and the Vac-Mat system of clamping technology.

About The Company:

Name: Thame Workholding

Benefits Achieved:

- VISI permits easy construction of 3D models, with automatic, detailed 2D drawings, directly from the master geometry.

- EDGECAM allows the production of 20 complete sets of jaws, with un-manned overnight, ‘lights-out’ machining.

- The joint software platform has given Thame added confidence in their existing product range, and in developing new bespoke workholding solutions.

Loading...

Loading...