.jpg)

Mould & Die

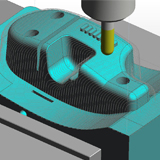

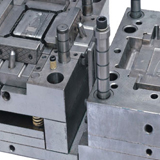

Whether producing moulds, dies, prototypes or patterns, EDGECAM enables cost-conscious manufacturers to use the power and performance normally only found in high-priced CAM systems. Mould and die manufacturing requires precise cutting, full machine simulation abilities and exacting finishing abilities for complex parts. With EDGECAM, you get best in class prismatic machining combined with powerful 3D solid and surface machining strategies.

Machine your cores, cavities and mold plates with just one system – EDGECAM

Features at a glance:

- High Speed Machining – EDGECAM optimizes cycles to help you make the most of this powerful machining method to deliver faster turnaround and a superior finish. Implementing smooth links between levels and regions, so the machine tool can maintain its feed rate.

- Automatic Feature Recognition – EDGECAM Solid Machinist uses automatic feature recognition tools to inspect prismatic solid models and identify machinable features. EDGECAM identifies pockets, bosses and hole feature attributes to select the appropriate tools and machining strategies.

- Intelligent Roughing Cycle applies the most efficient approach move for each region of the model and creates trochoidal moves to avoid full width cuts, automatically adjusting the toolpath for efficient and safe machining, improving cutting conditions and allowing higher machining speeds to be maintained.

- Adaptive Rest Roughing defines a subsequent roughing strategy with a smaller tool, only removing material left behind by the preceding larger tool – eliminating unnecessary air cutting.

- Advanced Machining with Intelligence – With an extensive suite of advanced 3D cycles that are ideally suited for rapidly generating toolpaths for all surface and solids machining needs, EDGECAM’s advanced machining cycles bring optimized toolpath control, reduced cycle times and an overall higher level of machining efficiency.

- Powerful Finishing Strategies offer intelligent lead and link moves for a variety of finishing techniques with advanced options allowing you to optimize the toolpath for higher speed machining and reduce or eliminate the need for costly and time-consuming manual finishing.

- Rest Finishing cycles allow the user to employ a larger tool for the majority of the part and then re-machine discreet areas to remove uncut material using a smaller tool, reducing cycle time and improving the surface finish.

- Productivity Toolbox – EDGECAM increases overall productivity with an innovative suite of support utilities including excellent toolpath simulation, a unique wizard approach to post processing, a comprehensive tooling database, intuitive and flexible machine tool communications and a web enabled job management system.

- Guaranteed Data Integrity – EDGECAM Solid Machinist seamlessly loads native files from major CAD systems including Autodesk Inventor®, Solid Edge®, SolidWorks®, Pro/ENGINEER®, Pro/DESKTOP® and CATIA V5. EDGECAM also accepts files in the following independent formats: IGES, DXF, VDA, Parasolid ® and ACIS.

- Reduced Programming Time – EDGECAM Strategy Manager reduces programming time by capturing best practice and machining knowledge into strategic metal removal templates. The strategy templates are stored in EDGECAM’s knowledge-base, where they can be used to quickly and reliably reproduce components for a variety of parts, dramatically reducing programming time and providing optimized and consistent repeatability.

To help you realise maximum return on your investment, our industry professionals will review your manufacturing process and supply you with automation tools in EDGECAM that will consistently capture best practice and give you optimized repeatability.

Loading...

Loading...